How To Choose An ESD Floor Mat

July 31, 2015

How to Choose an ESD Floor Mat

Choosing An ESD Floor is an Important Step in Eliminating ESD Damage

An ESD Floor mat is a very important part of a Static Protected Area. ESD mats are designed to eliminate static on its surface and of people standing upon it. A conductive material embedded within the mat draws in all the static and sends it to ground (earth). This is usually accomplished by connecting the mat to ground (typically the center screw of an outlet) with a floor mat ground cord. It’s important to wear ESD footwear such as heel grounders or ESD shoes when using an ESD floor mat, otherwise the static will stay on the body.

A quick search online or in ESD catalogs reveal a myriad of ESD floor mat options. What are the main considerations in choosing an ESD mat?

- Intended Use: Where are you putting the floor mat? Different styles work best in different locations.

- Material: Are you trying to protect your floors from wear-and-tear? The floor mat material makes a difference.

- ESD Properties: Not all ESD floor mats have the same ESD properties.

ESD Mats: Intended Use

ESD mats are generally found in three categories: Anti-Fatigue, Floor Runners and Floor Tiles. The type you choose depends on the intended use: Will people be standing on them for long periods of time? Choose an ESD Anti-Fatigue Mat. Do you need to cover the floor? Will wheeled carts need to roll over them? Choose a ESD Floor Runner. Do you have a large are to cover? ESD Floor Tiles may be your answer.

ESD Mats: Anti-Fatigue Matting

ESD Anti-fatigue mats, research shows, make a more comfortable worker, which makes a more productive worker with fewer injuries and increased productivity! ESD Anti-fatigue comfort mats are essential where workers stand to help ease leg, foot, and lower back fatigue and pain. Anti-fatigue mats come in a variety of styles and thicknesses to meet your needs and budget. Some are made from spongy foam material that is soft to the touch and others are made from rubber that may feel hard at first. You need to stand on a mat for an extended period of time to truly evaluate it. You may have to try our several different types to find the style you prefer.

ESD Mats: Floor Runners

“Floor runner†is a term that is used to describe mats that are long and narrow and that cover large areas. ESD Floor runners are typically found in building entrances, hallways, and in front of long workstations. They are usually thin so as not to be a trip hazard and provide little, to no anti-fatigue comfort. Common ESD Floor runners may have a V-Groove or a smooth surface. Some runners are designed to be durable and ridged enough to to be used with rolling ESD chairs.

ESD Mats: Floor Tiles

In some applications, it is preferable to cover a large section of a floor or the entire room with ESD matting. ESD tiles are used like puzzle pieces, interlocking together to build out large floors. ESD tiles can come in laminate, vinyl or rubber tiles. Laminate tiles are usually thin and ridged and many types require you to glue them down. Rubber tiles can be larger and thick and provide anti-fatigue properties. Some vinyl tiles are extremely durable, able to withstand forklifts. A benefit of non-glued down ESD tiles is that they can be disassembled and reconfigured or moved to a new location.

ESD Mats: Composition:

ESD floor mats are usually made from vinyl or rubber. Vinyl mats may be softer and less expensive, but are less durable than rubber mats. The most durable mats are made from rubber in which a single layer is molded into shape. Some floor mats use both: a durable rubber top layer and a spongy vinyl bottom. These mats may sound like the best of both worlds, but tend to delaminate over time and fall apart. Thickness, texture, and cushioning of the mat are also concerns depending on the application. Regardless of composition, all mats should meet or exceed the requirements of ANSI ESD-S20.20 (see below).

ESD Mats: Electrical Performance:

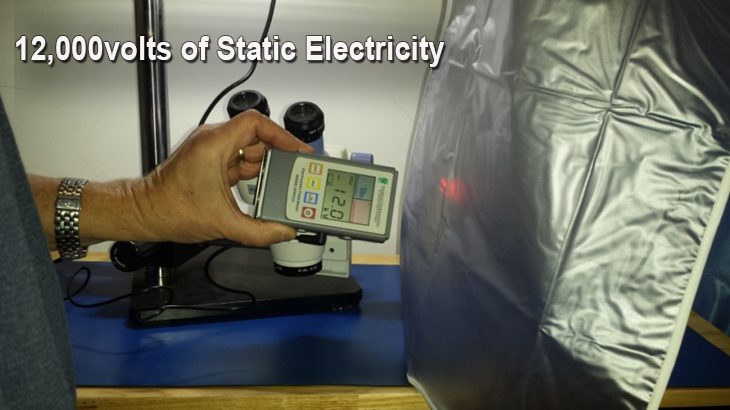

All static control mats are not created equally. The terms insulative, conductive, and dissipative are all terms that subdivide ESD materials based on their individual surface resistance. Surface resistance is a measurement of how easily an electric charge can travel across a medium (Visit here to learn How To Test ESD Mats). For most applications, ESD floor mats should be in the conductive range. Floor mats can become dirty over time which effects their ESD properties, so you want to start with a conductive mat to ensure you are grounded. Conductive materials have a surface resistance of less than 1 x 10^ 5 ohms/square. Dissipative items have a surface resistance of more than 1 x 10^ 5 ohms/square but less than 1 x10 ^11 ohms/square. An insulative material is one that has a surface resistance of greater than 1 x 10 ^12 ohms/square.

ESD Mats: Sizes:

ESD floor mats typically come in workstation sized mats such as 2’x3’ and 3’x5’, interlocking sections or in long rolls. The material is easy to cut and has a long shelf life so if you have more than one area to cover or expansion is a possibility, purchase a full roll and cut pieces as needed. Many suppliers also provide ready-to-use pre-cut mats with grounding hardware already installed. These mats can be more expensive, but it can also be a great time saver.

Conclusion:

When choosing an ESD mat, first use your specific application to narrow your choices, such as mat material and electrical properties. Carefully plan and budget your workstation so that you can choose to purchase a full roll or a pre-cut mat. Finally, do not let cost dictate your decision – saving a few dollars on low-quality matting could have very costly consequences via catastrophic damage, latent failures and customer complaints.

For help choosing your ESD mat, please call Transforming Technologies at 419-841-9552 or email info@transforming-technologies.com

View Transforming

Technologies ESD Floor Mats here:

http://mx.transforming-technologies.com/esd-floor-mats/

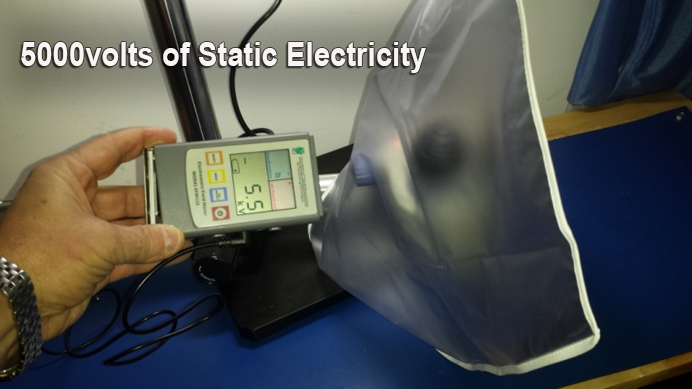

ANSI/ESD S2020, the industry standard for ESD control programs, states that all nonessential insulators should be removed from the ESD protected area.

ANSI/ESD S2020, the industry standard for ESD control programs, states that all nonessential insulators should be removed from the ESD protected area.