The Wireless Wrist Strap – Do They Work?

We Put Them to the Test! And They FAIL!

The wireless wrist strap has been available for over 10 years. Â We have seen them used in the electronics manufacturing and other assembly applications and have received several inquiries about their performance.

In this blog, we test and report on the effectiveness of the wireless wrist strap. Our results indicate wireless wrist straps fail to ground operators or keep operators sufficiently neutral. Read why the wireless wrist strap system results in a potential nightmare of problems and view the hard data that proves they don’t work.

Background: The Wireless Wrist Strap Dream

It would be nice to be able to effectively drain the charge from a person without them tethered to a work station with standard wrist straps or other ground connection.  ESD flooring and footwear is an option, however it can require a significant investment for it to be effective. Hence, the dream of the wireless wrist strap.

So what about the wireless wrist strap? The advertising says “This compact wrist strap eliminates static without the need for a pesky grounding cord. This allows you freedom of movement so you can leave your work area without needing to unclamp yourself and lose your anti-static protection.â€Â It also states that the band “…ensures that you have a much smaller static build-up and dissipates it quickly.â€

Wireless Wrist Straps vs. Physics

That all sounds wonderful in theory, unfortunately it does not work as advertised.  Most companies follow the ANSI/ESD S20.20 standards for their ESD Control Programs which requires human body voltage to be less than 100 volts and the wireless wrist strap does not meet the requirements of the standard.

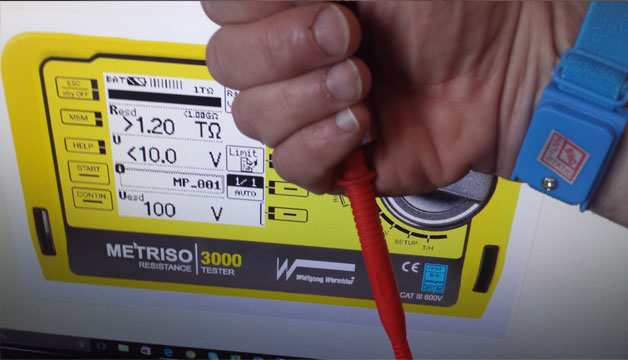

The standard states “All personnel shall be bonded or electrically connected to the grounding/equipotential bonding system when handling ESDS items.†The standard goes on to list the requirement of a resistance between the operator and ground of less than 35 megohms. This requirement seems quite impossible to meet with the wireless wrist strap.

Resistance to Ground of person wearing a corded wrist strap

Resistance to Ground of person wearing wireless wrist strap

But what if you are not tied to the industry standard and just want to make sure that you are not generating excessive voltage that could harm electronic devices or assemblies? The voltage generated and stored on the person is what is important. So let us conduct another measurement that compares the voltage generated on a person that is a: not grounded, b: grounded through a conventional wrist strap/cord system and c: a person wearing the wireless wrist strap.

The Walking Test

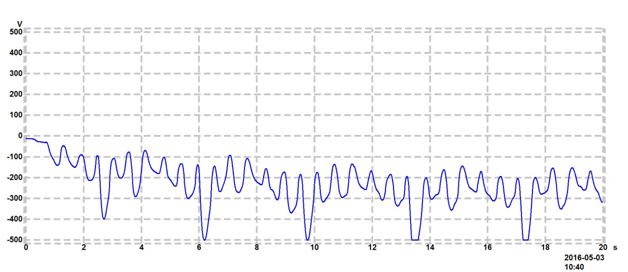

For this test we will use the Warmbier WT5000 walking test instrument.  This instrument measures and records the voltage on a person while walking or simply standing. To measure the voltage we held the test electrode on the instrument and repeated the six step walking test described in ANSI/ESD STM97.2 – Voltage Measurement in Combination with a Person.

You see that from Figure 1 that the voltage on the person wearing standard shoes on a tile floor and no wrist strap was greater than -500 volts.  This voltage is well in excess of the damage thresholds for many devices today.   Next we will try the same floor and footwear but the operator will wear a standard wrist strap with coil cord (Figure 2).

In this case you should notice that the voltage is minimal.  The peak voltage was -1.41 volts and the valley was +0.46 volts.

Finally, we test the same floor and footwear with the wireless wrist strap (Figure 3).

The graph in Figure 3 shows that while wearing the wireless wrist strap, voltages of greater than

-100 volts were reached within one second of the test and peak voltages exceeding -500v were reached in less than 10 seconds.

Wireless Wrist Straps are Unacceptable

So in addition to not being electrically bonded to ground, the wireless wrist strap does not prevent charge build-up or decay charge at a rate that is acceptable for handling electronic devices.

It would be nice to be able to handle electronic devices without that bothersome coil cord getting in the way or without having to invest in a flooring and footwear system, however the reality is that a person must be physically and electrically attached to ground to drain charge from their body.

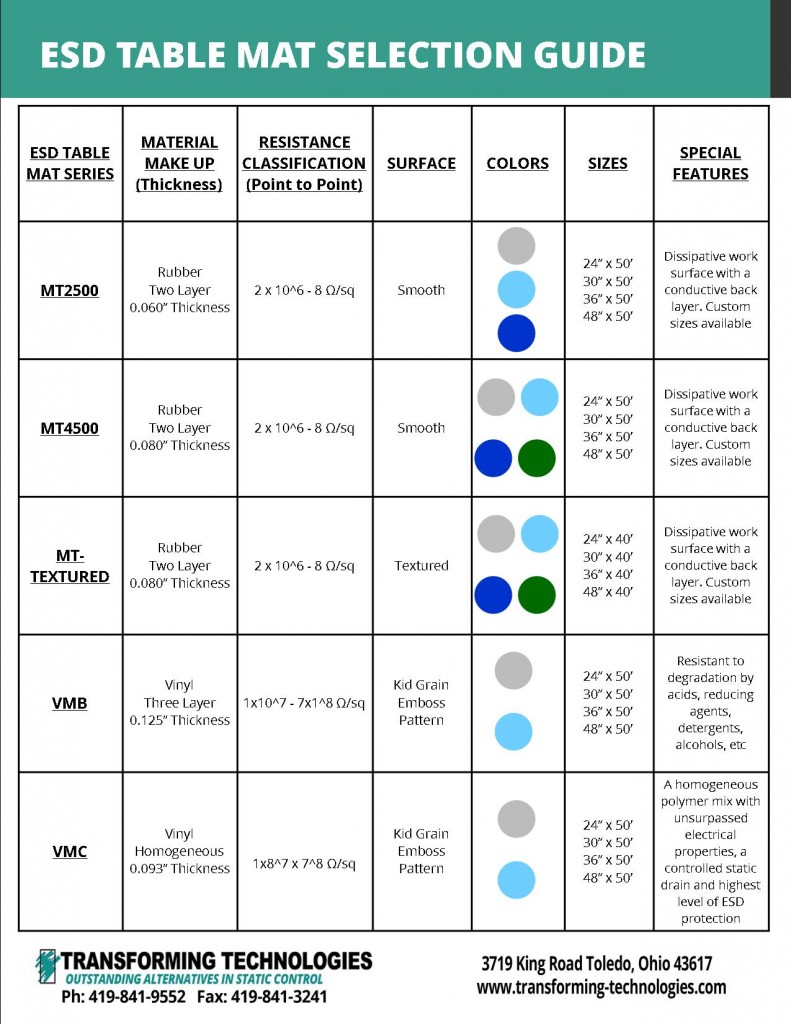

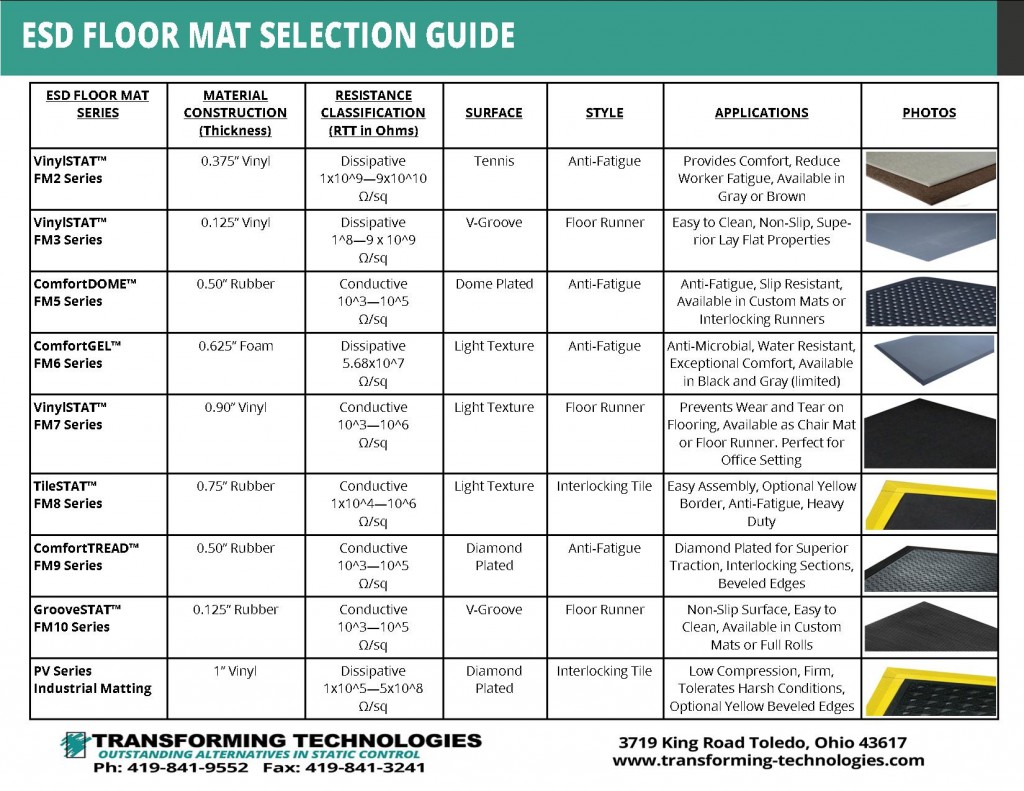

Introducing Transforming Technologies ESD Mat Selection Guide

Introducing Transforming Technologies ESD Mat Selection Guide