Introduction

When a tool or tester on your line stops working, everyone scrambles to correct it. Such process halts slow the manufacturing process, and cause lower product throughput. Achieving the best equipment up time is a key element in achieving profitability in any automated factory.

When tool halts are random they are quite difficult to troubleshoot. Their frequency could be every few minutes or just once a month!. Equipment diagnostics often provide no information as to the cause of these random equipment problems.

Finding the Cause of the Problem

When an automated process halts sporadically, both the hardware and the software are suspect. Often there are lengthy finger pointing discussions between the hardware and software engineers which does not bring the problem any closer to a solution.

In some cases, the problem is neither the hardware nor the software. Rather it can be electromagnetic interference (EMI) generated by electrostatic discharge (ESD). The EMI generated by ESD can exceed immunity levels of automation equipment. ESD discharges occur so fast (typically in nanoseconds) that they radiate EMI extremely efficiently. This very short transient EMI is surprisingly high in amplitude because all of its energy is packed into a few nanoseconds. Further, these short EMI transients are not detected by spectrum analyzers.

An electrostatic discharge occurs when charged objects come close enough to ground to cause a breakdown of the air gap between the object and ground. Transferring wafers or reticles with a grounded robot or plugging a charged IC into a socket are obvious examples of such ESD events. ESD is well-known to cause damage directly to reticles, wafers and ICs.

Once an ESD event injects an EMI transient into a tool, it is efficiently transmitted through the electronic circuitry within the tool. Circuit boards are laid out to distribute high speed clock signals and thus EMI transients are also transmitted efficiently.   It is important to realize that for EMI to cause an error it must be induced in the circuitry simultaneously with a critical circuit operation. Thus, many EMI events can occur before one causes a tool error to occur. This is also the reason that this type of tool halt is random in nature.

The tool halt, may be accompanied by a difficult-to-interpret error message. Equipment diagnostics succeed in making the problem look like a software bug, certainly not EMI from an ESD event.

Conducted vs. Radiated EMI

When an ESD event occurs, the rapid transfer of charge results in currents that may be hundreds of Amperes. The entire discharge typically occurs in a time interval measured in nanoseconds. While some of the energy is dissipated in heat (which damages silicon and metallization), a significant portion of the energy becomes electromagnetic radiation. This generally occurs in the 25 MHz to 2 GHz frequency range. It may be conducted away from the site of the ESD event through a metal structure or a power line, or it may radiate through the air. In either case it may affect equipment at a considerable distance from the location of the ESD event.

Identifying ESD caused EMI

ESD diagnostics are not part of the toolkit of most production engineers. As an illustration, a manufacturer of microprocessors was experiencing random equipment problems with one of nine steppers in the photolithography area. In-house engineers and the equipment manufacturer’s field service engineers tried software upgrades and replacement of major stepper components. After 6 months of frustrating and unsuccessful investigation, a well known ESD consultant made measurements with an antenna and a wide band digitizing oscilloscope. He detected a random signal on the power supply line of the stepper occurring about once a minute. The random nature of the signal pointed to EMI as the possible cause of the problem.

An electrostatic field-meter found static charge developing on a panel and identified the cause of the problem in less than one hour. One of the wall panels above the stepper was not connected to ground. This large isolated conductor was becoming charged, and then discharging to the nearby grounded wall framing. The EMI from the ESD event was causing the equipment interrupts.

Diagnostic Clues

When an unexplained phenomenon occurs in a random fashion on some tools of a given tool type but not all of them that is a clue. When a “software bug†is evident on some tools but not all but the tools have the same Rev Level of software, that is another clue. Most importantly, do not wait six months before considering this cause for the problem. There are tools for the detection of these transients that range from multi Giga Hertz digitizing oscilloscopes to simple EMI locators designed to be sensitive to these transients.

Conclusions

Many equipment failures are the result of random ESD events and a great deal of production and engineering time is wasted pursuing phantom software problems.

Charge generation is unavoidable in many high tech manufacturing processes due to the presence of easily charged insulating materials. It is impossible to assure that everything is continuously connected to ground and that ESD events will not occur. 5 Making ESD control part of your arsenal of tools to keep your factory running smoothly is an important addition.

References

1. Levit, L., Menear, J.â€Measuring and Quantifying Static Charge in Cleanrooms and Process Toolsâ€, Solid State Technology, February 1998. PennWell.

2. Honda, M., et al, “Method of Observing ESD Around Electronic Equipmentâ€, ESD Symposium, September 1996, ESD Association, 7900 Turin Road, Rome NY 13440.

3. Peters, L., “ESD Can Be a Tool’s Worst Enemyâ€, Semiconductor International, September 1997, Cahners Publishing Company.

4. SEMI E78-0998 “Guide to Assess and Control Electrostatic Discharge (ESD) and Electrostatic Attraction (ESA) for Equipment, September 1998, SEMI.

5. Galatowitsch, S., “Terminating Static in the Cleanroomâ€, Cleanrooms, April 1998, PennWell.

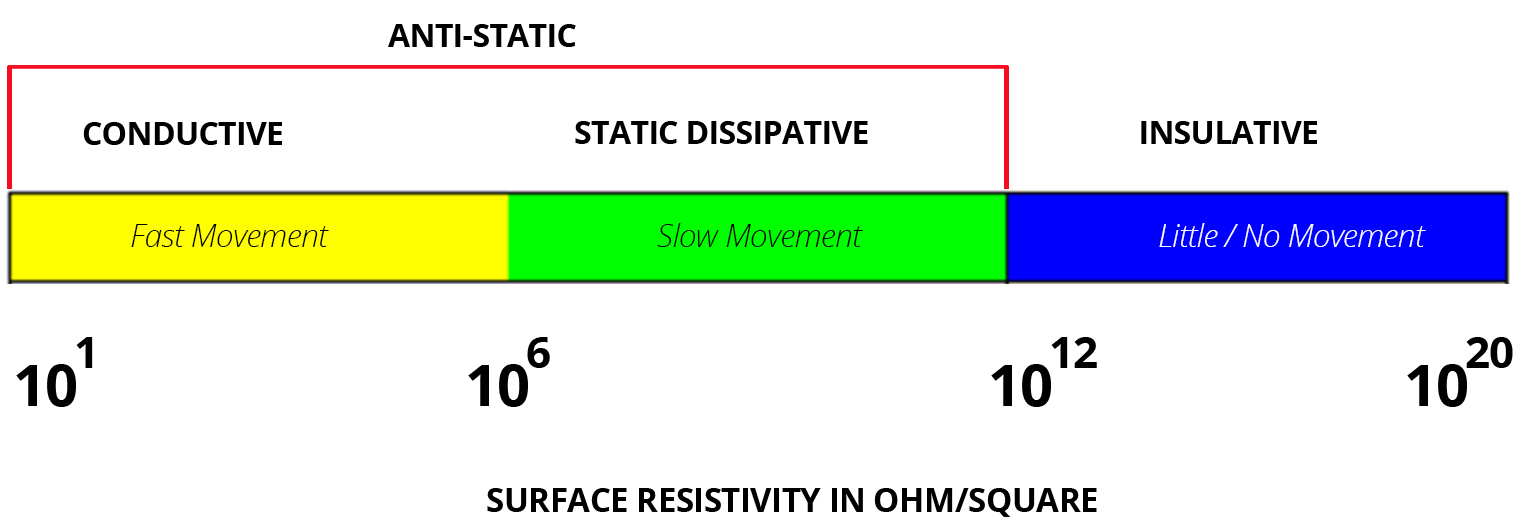

The Four Rules Of ESD Control

The Four Rules Of ESD Control