One Meg Vs Two Meg Heel Grounders

Introduction

Have you ever wondered what it means when a heel grounder described as having a “1 meg resistor”? or a 2 meg resistor? The size of a current limiting resistor is often included in the description of personal grounding products, but what does it mean and how concerned should I be with the size of the resistor when I am buying heel grounders? Today we will answer these questions but first some background:

What is a Resistor?

A common resistor

A resistor is a component of an electrical circuit that resists the flow of electrical current. A resistor has two terminals across which electricity must pass, and is designed to drop the voltage of the current as it flows from one terminal to the next. A resistor is primarily used to create and maintain a known safe current . Most grounding products have a current limiting resistor and it is most commonly one megohm, rated at least 1/4 watt with a working voltage rating of 250 volts. This ensures that the flowing current will be within safe levels.

Heel Grounders and ESD Protection?

Heel grounders discharge static from a person to ground by connecting the person to a grounded walking surface. A heel grounder is made from a conductive material and is worn on each shoe. A conductive ribbon placed inside the wearer’s shoe or sock makes electrical contact with the skin through perspiration. The ribbon is joined to a resistor which limits current should accidental exposure to electricity that may occur. The other end of the resistor is joined to a conductive sole. This sole contacts a grounded ESD floor mat or ESD flooring system. Heel grounders should be worn on both feet to maintain ground contact while walking. UL and OSHA recommends a minimum of 1 megohm resistance to ground (RTG) in order to limit current for safety purposes.

Types of Heel Grounders?

Heel Grounders come in a variety of styles:

- Cup Style: Made with two reversible soles for longer life span.

- Foot Grounder: Provides a more complete path-to-ground due to wider contact area and heel-to-toe coverage.

- Disposable: Strip of conductive material is applied to shoe. Economical and perfect for one time use.

- Toe Grounder: Ideal for high heels when standard heel grounders won’t fit properly.

Resistors and Heel Grounders

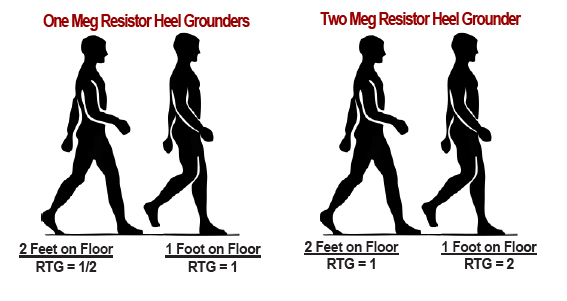

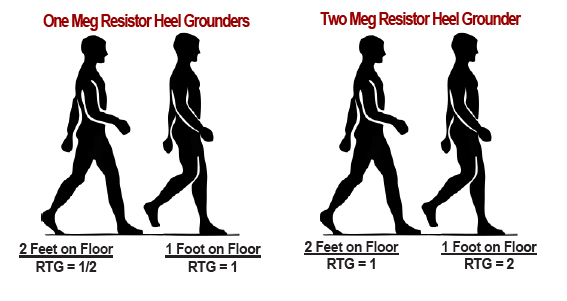

Heel grounders come with either a 1 megohm or 2 megohm resistor. When one foot is on the ground, a 1 megohm heel grounder gives you an RTG of 1 megohm and a 2 megohm heel grounders results in 2 megohm RTG. But when both feet are on the ground, the sum of the resistors yield a RTG of 1/2 that measurement.

For example:

- When you wear two, 1 megohm heel grounders and have both feet on the floor, your RTG is only 1/2 megohm, NOT 1 megohm!

- If you wear two, 2 megohm heel grounders an have both feet on the ground, your RTG is 1 megohm.

- By wearing two heel grounders with a 2 megohm resistor you are complying with UL and OSHA at all times.

This can be sometimes confusing. So we made a diagram to illustrate:

Conclusion

Heel grounders are an effective and popular way to ground mobile personnel in ESD areas. Heel grounders use built in resistors to limit any potential current that flows through the device to ensure operator safety. The size of the resistor that you use depends on the standards of the specific operation, but by wearing two heel grounders with a 2 megohm resistor you are complying with UL and OSHA at all times.

To learn more about ESD heel grounders and Resistors, visit Transforming Technologies.com