ESD Wrist Strap Testing and Monitoring

September 19, 2013

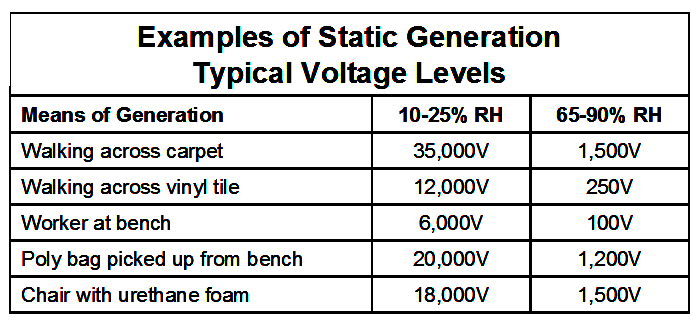

One of the requirements of any quality ESD control program is to minimize the charge (also called voltage) on operators. When operators are charged with static electricity, they can transfer this charge to the product and possibly cause damage or destruction. One effective way to reduce static charging on people is to ground them through the use of a wrist strap and coil cord. When working properly, the wrist strap system (band and coil cord connected to common point ground) can control voltages on people down to 10 volts and less and limit damage.

One of the requirements of any quality ESD control program is to minimize the charge (also called voltage) on operators. When operators are charged with static electricity, they can transfer this charge to the product and possibly cause damage or destruction. One effective way to reduce static charging on people is to ground them through the use of a wrist strap and coil cord. When working properly, the wrist strap system (band and coil cord connected to common point ground) can control voltages on people down to 10 volts and less and limit damage.

Wrist straps are the most common and effective way to eliminate static on personnel, but they are also the ESD control device that is most likely to fail over time. A broken wire in the coil cord, a dirty cuff interior, incorrect wearing of the strap (too loose or placed over clothing), and high skin resistance are just a few of many causes of wrist strap failure. If wrist straps fail, the static charge on an operator will increase and may cause ESD damage without the operator even noticing. Therefore, it is imperative that measures are taken to assure that the operator is properly grounded when wearing a wrist strap.

The PDT800 is a deluxe “Near-Fail” wrist strap and foot wear combination tester with a digital read out, “near-fail” LED indicator, human body noise filtration, and options to test wrist strap only, foot only, or both wrist and feet.

ESD Test Stations

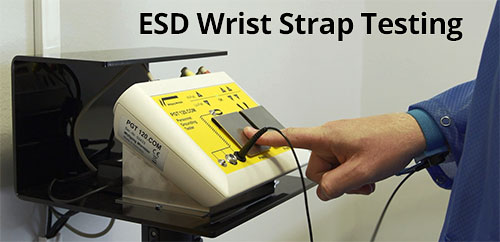

One way to assure that the wrist strap system is working correctly is to use an ESD Test Station. The ESD Test Station assesses the resistance of the wrist strap system (including the operator) and provides a pass/fail indication. Some more advanced test stations will also provide the actual resistance measurement and can even log test data on a computer. But the frequency of testing differs from company to company. Some require testing just once at the beginning of the shift. Other companies may require re-testing several times a day. Regardless of how many times an operator tests, there is a risk that the wrist strap will fail at some point during a shift. Constant Monitors can eliminate this risk.

Transforming Technologies offers several testing station options that range from wrist strap monitors (WST200), wrist strap and footwear test stations (GTS600K), wrist strap and individual foot test stations (GTS900K), test stations with “near-fail†technology and digital display (PDT800K). These testing stations function with a standard wrist strap and coil cord using a banana jack connector and standard heel grounders.

Constant Monitoring

An ESD wrist strap plugged into a Constant Monitor. The monitor will alarm if there is a problem.

If a wrist strap fails the test at the beginning of a shift, the question arises, “When did the failure take place and how much product was handled after the failure?†Constant monitors provide assurance that the wrist strap system is working and alarms immediately if there is any disconnect from the operator to ground. There are several benefits to constant monitor systems:

- They provide immediate notification of a problem and alert the operator to not handle the product until the problem is resolved

- They monitor the wrist strap at the work location, eliminating the possibility of a functional wrist strap but a defective ground attachment

- They eliminate the need for recording and storing test results

- Some units will also monitor the work surface to verify that it is still connected to ground

The downside of constant monitors is that each operator must have their own dedicate monitor, which can be a costly initial investment. But the savings overtime of product damage during manufacturing and lower warrant claims can make up for the constant monitor costs.

Transforming Technologies offers several low cost constant monitor options that range from monitoring a single operator (CM400), an operator and a work surface (CM410), and two operators and a single work surface (CM420). These monitors function with a standard wrist strap and coil cord using a banana jack connector.

Summary

Wrist straps are the most common method for removing charge from operators handling ESD sensitive products, but they need to be tested often to ensure they are working properly. ESD Test Stations can verify wrist strap operation but there is still a risk of wrist strap failure in between tests. Constant monitors solve this problem and can provide assurance that the system is working as designed and the products are being handled safely at all times.