ESD jackets, also commonly known as ESD smocks, ESD lab coats or ESD garments, offer protection from electrostatic fields generated by clothing on the user’s body. ESD jackets are worn where ever static damage is a concern. ESD jackets differ from common work garments because they are made with a grid of conductive fibers throughout. The grid creates a “Faraday Cage” effect around the body of the operator that shields charges generated from the operators clothing from damaging ESD sensitive devices. The conductive fibers also lowers the static charge generation of the jacket(also refereed as tribocharging) to a safe level.

ESD Jackets as part of a complete Quality Control Program.

ESD jackets are the most visible sign of ESD protection and any facility that mandates ESD garments demonstrates a commitment ESD protection. ESD jackets are a recommended addition to a program that already includes typical grounding measures, such as wrist straps and heel grounders. This is because of the potential hazard of the operator’s clothing. The ESD TR20.20-2008 states: “While a person may be grounded using a wrist strap or other grounding methods, that does not mean that insulative clothing fabrics can dissipate a charge to that person’s skin and then to ground. Personnel clothing usually is electrically separate or isolated from the body.â€Â

How To Choose an ESD Jacket?

A quick search online reveals numerous options for ESD jackets. We have summarized the main considerations when choosing ESD jackets:

ESD Garments come in many shapes and sizes. Typical distinctions are:

- Fabric Composition

- ESD Properties

- Collar Options

- Sleeve Terminations

- Length

- ColorÂÂ

- Embroidery

The jackets you choose will most likely depend on style preference but the ESD properties should be the first priority to ensure the jackets will protect against ESD as intended.

ESD Properties

There are three classifications of ESD jackets per ANSI / ESD S20.20: an ESD Garment is defined as either:

- Level 1: Static Control Garment (surface resistivity of < 1 x 10^11 ohms resistance);

- Level 2: Groundable Static Control Garment (surface resistivity of < 1 x 10^9 ohms resistance); or

- Level 3: Groundable Static Control Garment System (surface resistivity of < 3.5 x 10^7 ohms resistance).

ESD jackets are classified by ESD properties (how conductive they are), with level 1 being the lowest and level 3 is highest. Level 1 jackets are typically the lowest cost but because the ESD properties are low they may wear out faster and need to be replaced more often. Level 3 jackets are conductive enough that the fabric can be used as part of the ground path for wrist straps which allows for safe, hands-free grounding. Level 2 is in the middle.

How to Test ESD Properties

There are several ways to test an ESD jacket but for general purposes, a sleeve-to-sleeve measurement is the most important. This test is used to confirm electrical continuity across garment panels and sleeve components. At minimum, an ESD jacket must be dissipative (surface resistivity of < 1 x 10^11 ohms resistance). This test is performed with a Surface Resistance Meter. The ESD properties should be included in the data sheet for the ESD jacket from the manufacturer. It is always recommended to regularly test your ESD jackets because wear and tear and laundering will effect the ESD properties over time.

Fabric Composition

Fabrics composition will vary by the manufacture but are typically made with a combination of carbon with polyester fabric or a cotton polyester blend. Commonly, the fabrics are described with a percentage. For example, 88% polyester and 12% carbon. Your choice of fabric will be determined by operator comfort and ESD performance. You may choose a lightweight polyester for warmer climates or a cotton polyester blend for cooler climates.

The amount of carbon in the jacket is important to note because this is the element that makes the jacket “ESD safeâ€Â. The more carbon, the better the anti-static performance. Lower cost ESD jackets are available with a carbon content of less than 5%, but they may not perform well or last as long as jackets with higher carbon content.

Collar Options

Collar options typically include Lapel, V-Neck or Military style. The type of collar you choose will be based on user comfort and sensitivity of the application. The various collars allow more or less clothing to be exposed to your environment. V-Neck collars are the most open and may be cooler to wear. Military Collars covers the most clothing, but may more uncomfortable to wear. Lapel collars are in between the two and are the most commonly used collar.

Sleeve Terminations

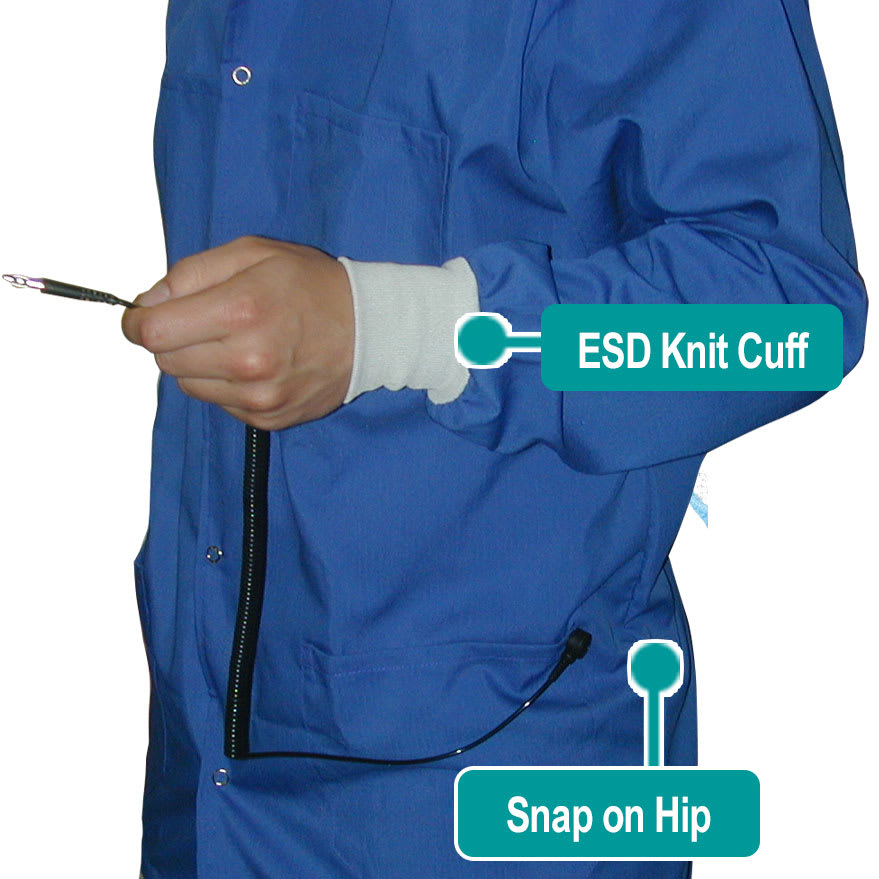

ESD jackets have either a Snap Cuff or an ESD Knit Cuff. The snap cuff includes three snap that adjusts for a proper fit and are typically cheaper. The three snap cuff is ideal when you already have wrist-straps, or in cases when wearers find the cuffs a little too snug. A wrist strap can be snapped to the garment sleeve and cord is attached at the hip pocket to ground both the person and the jacket.

An ESD Knit Cuff is very similar to the cuff on the end of a sweatshirt and allows for hands free grounding. ESD Knit cuffs form a contact path around both of the wearer’s wrists. The garment and wearer can then both be grounded by attaching a ground cord to the 4mm stainless steel snaps on the hip pocket.

Short sleeve jackets are also available from some manufacturers.

Length

ESD jackets come in three lengths: waist length, 3/4ths and full length. The length you choose depends on the sensitivity of the application and the comfort of the wearer. Waist length jackets leaves the most clothing exposed but may be cooler. Full length jackets cover the most clothing by going down to about the knees and are sometimes referred to as lab coats. 3/4ths length jackets come down to mid-thigh and are between the waist length and full length.

Colors

ESD Jackets come in many colors, with blue the most common. The color has nothing to do with performance and is only preference by the company using them. Many companies will color code their employees with their ESD jackets. For example, employees may wear blue, management wears black and visitors wear white. High-Visibility jackets are available for safety reasons. Color options vary by manufacturer, and by fabric. Jackets may also be died to match company colors but will have a high minimum order quantity.

Embroidery of ESD jackets

Many companies choose to embroidery their company logo or employee name onto their ESD jackets. Sublimations, screen printing and patches are also ways to add logos or names.

Conclusion

ESD Jackets are an important part of an ESD program. There are many styles to choose from, but ESD properties should be the most important factor in choosing an ESD jacket. After you ensure your jacket will protect your application, you have your choice of fabrics, collars, sleeves, and colors.