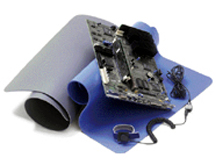

Covering your work surface with ESD material is a basic step in ESD prevention.  With a proper ESD worksurface, static is safely removed from items placed on the surface. There are several types materials used, but the most common is 2 layer ESD rubber. ESD rubber is constructed with a rugged dissipative top layer and a conductive black bottom layer. For ESD purposes, materials are classified by their resistance to the movement of electricity. The dissipative top surface allows charges to drain from its surface in a controlled manner, sending it to the bottom conductive layer. The conductive bottom layer has a low electrical resistance and quickly sends the charge to ground via a ground cord that includes a current limiting resistor for safety. The top layer is also extremely durable, offering excellent resistance to hot solders, soldering irons and most solvents.

With a proper ESD worksurface, static is safely removed from items placed on the surface. There are several types materials used, but the most common is 2 layer ESD rubber. ESD rubber is constructed with a rugged dissipative top layer and a conductive black bottom layer. For ESD purposes, materials are classified by their resistance to the movement of electricity. The dissipative top surface allows charges to drain from its surface in a controlled manner, sending it to the bottom conductive layer. The conductive bottom layer has a low electrical resistance and quickly sends the charge to ground via a ground cord that includes a current limiting resistor for safety. The top layer is also extremely durable, offering excellent resistance to hot solders, soldering irons and most solvents.

Transforming Technologies has the most cost effective ESD rubber available. The MT4500 series is a smooth rubber surface in light blue, royal blue, gray and green. The MT4000 Textured series ESD rubber matting is made of 100% co-extruded rubber with a textured surface in light blue, royal blue and gray.

Contact Transforming Technologies for your work surface ESD rubber needs.