The conveyor belt is an indispensable part of the automatic transportation equipment. But the conveyor belt can be a major generator static electricity that can cause numerous problems, from static shocks to employees to catastrophic damage to components. The cause of static is friction, and on belt conveyors, the belt surface is continually rubbing the pulley surface, generating static electricity. As the conveyor continues to operate, the static charge will continue to accumulate and increase unless it is bled off (or discharged) in some manner. Conveyor and assembly trays can also create a static charge and shock employees.

Anti-static conveyor equipment exists, so when choosing the conveyor belt, pay special attention to whether the belt has anti-static characteristics. A surface resistance meter can be used to measure the anti-static properties of a conveyor belt. But if your equipment is not anti-static, then you must eliminate static in other ways. The first step in eliminating static is to measure it. If you can feel the static charge or receive shocks, then the charge is already way to high and needs to be addressed. Human feel static at 2000 volts, but components can be damaged with as little as 100 volts. A static field meter can be used to measure the static charge on your conveyor.

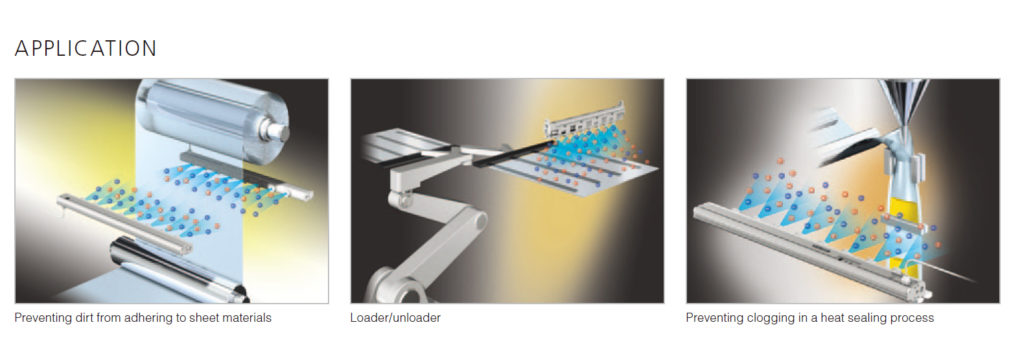

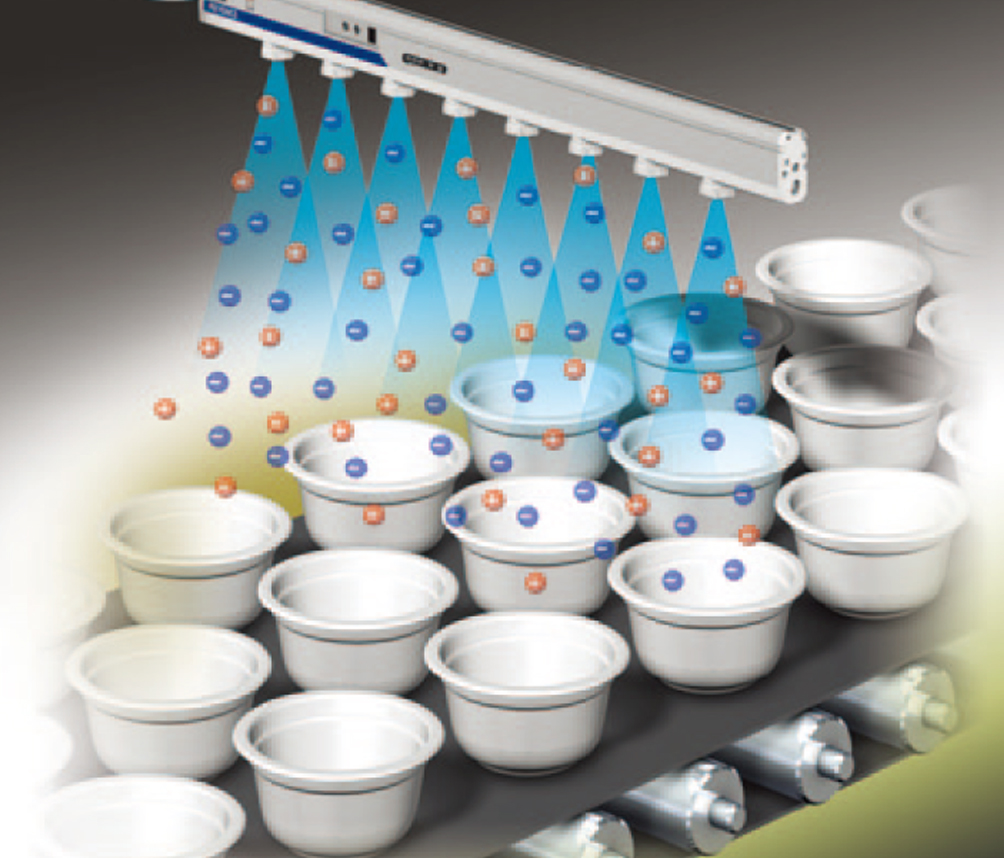

Drag chains can be a do-it-yourself solution to drain a charge, but they are not always practical or effective enough. Anti-static ionizers are the most effective method of eliminating static on conveyors. Ionizers blow specialized air that eliminates static charges. They are designed to be mounted overhead, or in targeted areas and can be effective without interfering with the movement of the conveyor or components. Ion bars are excellent for conveyors because they can cover wide areas with a relatively small footprint. A three fan overhead ionizer is also an effective ionizer for conveyors. If the target area for ionization is small, ionizing nozzles can be very effective. They provide a targeted stream of ionized air that can even be activated automatically with a photoelectric eye.

Placement:

This will vary by application. Mount

ionizers at friction points in your process and the locations of the biggest static

issue. Mount the ionizer as close to the problem area as possible, but not too

close that the ionizer does not have enough time to do its job. If your employees are getting shocked, you

will want to install the ionizer just prior to the employee exposure.

Conclusion:

Conveyors generate static due to friction, which can cause numerous problems. Anti-static ionizers are a very effective tool to remove the static charge.

View all of Transforming Technologies Anti-Static ESD Ionizers here.