Industrial ESD Floor Tile

January 22, 2013

December 3, 2012

Learn more about Transforming Technologies EFM115 Electrostatic Fieldmeter.

Learn more about Transforming Technologies EFM115 Electrostatic Fieldmeter.

August 5, 2012

Transforming Technologies has long lasting Cup Style ESD Heel Grounders in Color you want and with protection you need!

Transforming Technologies has long lasting Cup Style ESD Heel Grounders in Color you want and with protection you need!

Call Transforming Technologies at 419-841-9552 or email sales@transforming-technologies.com for a quote today!

July 24, 2012

ESD jackets come in many shapes and colors, not to mention fabrics, so it can be very difficult to choose the right jacket for your application. Now you have tried all the samples, haggled with salesmen, and have placed your first order, how do you care for your ESD jackets to ensure long life?

Answer: Wash in cool or cold water (90°F maximum) with any commercially available liquid detergent. Do not bleach. Hang dry or tumble dry on low heat. The carbon-suffused mono-filament nylon is sensitive to heat and should not be ex-posed to laundering heat in excess of 120°F or more.

June 26, 2012

Transforming Technologies is proud to announce the addition of the 5049 Series ESD Jackets and Lab Coats to our line of ESD Products.

The 5049 Series Garments are constructed with an anti static polyester and cotton fabric blend, making the jackets  effective as an ESD control device and extremely comfortable to wear. Superior workmanship provides reliable panel-to-panel continuity of the garment. The 5049 Series Garment maintains consistent continuity readings for up to 100 wash cycles.

effective as an ESD control device and extremely comfortable to wear. Superior workmanship provides reliable panel-to-panel continuity of the garment. The 5049 Series Garment maintains consistent continuity readings for up to 100 wash cycles.

The 5049 Series is available in a waist length jacket or a full length lab coat. The standard sleeve termination is a three snap adjustable fit cuff (ESD knit cuff with snap-to-ground feature is also available).

Features

For price and availability on the 5049 Series Garments or for information on any products in Transforming Technologies full line of ESD products, please call 419-841-9552 or email eric@transforming-technologies.com.

June 15, 2012

The Four Rules Of ESD Control

The Four Rules Of ESD ControlFollow these simple rules of ESD control and you will never be shocked (yes, we went there) by static damage.

1st Rule of ESD:Â Ground everything you can.

If you can attached a ground cord to it, do it. Grounding conductive materials sends any charge buildup to ground where it is neutralized.

2nd Rule of ESD:Â Avoid Insulators whenever you possibly can!

Insulators cannot be grounded and a potentially dangerous charge can build up fast. Remove everything you can made out of insulating materials, like plastics and Styrofoam.

3rd Rule of ESD: Use Dissipative materials whenever possible and ground them.

Get yourself a dissipative ESD Mat! Dissipative materials allow a charge to flow slowly and controlled to ground. Anything more conductive or more insulative is a problem.

4th Rule of ESD: Use an ionizer on any insulators and ungrounded conductors that can’t be remove.

Ionizers blow air full of positively and negatively charged ions that neutralize static on contact. They are the only way to control static on insulative materials.

May 1, 2012

Covering your work surface with ESD material is a basic step in ESD prevention.  With a proper ESD worksurface, static is safely removed from items placed on the surface. There are several types materials used, but the most common is 2 layer ESD rubber. ESD rubber is constructed with a rugged dissipative top layer and a conductive black bottom layer. For ESD purposes, materials are classified by their resistance to the movement of electricity. The dissipative top surface allows charges to drain from its surface in a controlled manner, sending it to the bottom conductive layer. The conductive bottom layer has a low electrical resistance and quickly sends the charge to ground via a ground cord that includes a current limiting resistor for safety. The top layer is also extremely durable, offering excellent resistance to hot solders, soldering irons and most solvents.

With a proper ESD worksurface, static is safely removed from items placed on the surface. There are several types materials used, but the most common is 2 layer ESD rubber. ESD rubber is constructed with a rugged dissipative top layer and a conductive black bottom layer. For ESD purposes, materials are classified by their resistance to the movement of electricity. The dissipative top surface allows charges to drain from its surface in a controlled manner, sending it to the bottom conductive layer. The conductive bottom layer has a low electrical resistance and quickly sends the charge to ground via a ground cord that includes a current limiting resistor for safety. The top layer is also extremely durable, offering excellent resistance to hot solders, soldering irons and most solvents.

Transforming Technologies has the most cost effective ESD rubber available. The MT4500 series is a smooth rubber surface in light blue, royal blue, gray and green. The MT4000 Textured series ESD rubber matting is made of 100% co-extruded rubber with a textured surface in light blue, royal blue and gray.

Contact Transforming Technologies for your work surface ESD rubber needs.

March 29, 2012

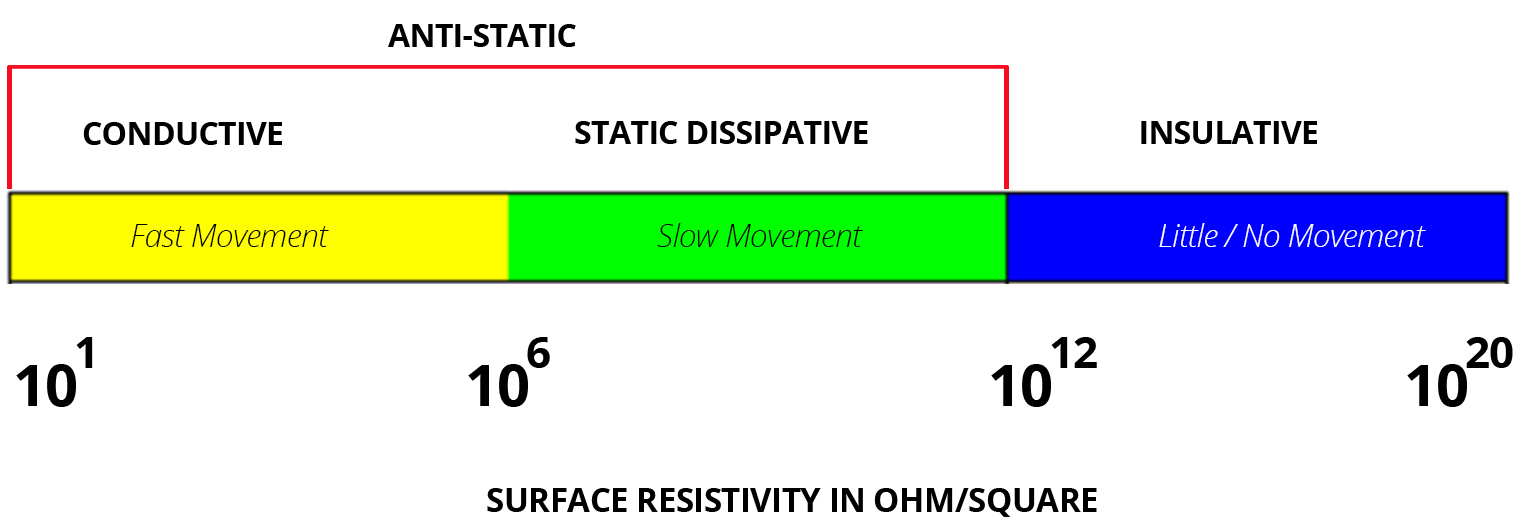

For ESD control purposes, materials are classified by how quickly electricity moves through the material. The speed is referred to as the “resistance” of the material i.e. Â how strongly the material resists charge movement.

The speed is measured in Ohms and is typically displayed in powers of 10 (example 10^3). The lower the number, the more conductive the material and may be considered “Antistatic”.

| Classification | Charge Movement | Resistance | Ohms | Is it Antistatic? |

|---|---|---|---|---|

| Conductive | Very Fast | Low Resistance | 10^3 - 10^ 5 | Yes |

| Dissipative | At a controlled speed. Fast but Slower than Conductive | Medium Resistance | 10^6 - 10^ 10 | Yes |

| Insulative | Slow or No Movement | High Resistance | 10^11 - 10^ 12 | No |

The following ranges and definitions are found in ESD Association or EIA standards publications:

Conductive materials: With a low electrical resistance, electrons flow easily across the surface or through the bulk of these materials. Charges go to ground or to another conductive object that the material contacts or comes close to. Conductive materials have a surface resistivity less than 1 x 10^5 Ω/sq or a volume resistivity less than 1 x 10^4 Ω-cm. Conductive materials are classified “Antistatic”.

Dissipative materials: For these materials, the charges flow through the material slowly and in a somewhat more controlled manner than with conductive materials. Dissipative materials have a surface resistivity equal to or greater than 1 x 10^5 Ω/sq but less than 1 x 10^12 Ω/sq or a volume resistivity equal to or greater than 1 x 10^4 Ω-cm but less than 1 x 10^11 Ω-cm.2. Dissipative materials are classified “Antistatic” and are considered to be the ideal range for ESD materials.

Insulative materials: Insulative materials prevent or limit the flow of electrons across their surface or through their volume. Insulative materials have a high electrical resistance and are difficult to ground. Static charges remain in place on these materials for a very long time. Insulative materials are defined as those having a surface resistivity of at least 1 x 10^12 Ω/sq or a volume resistivity of at least 1 x 10^11 Ω-cm. Insulative materials are not classified as “Antistatic”.

Anti-Static: Is a term used to describe materials that prevent the buildup of static electricity. Both conductive and dissipative materials are classified as Antistatic.  Insulative materials are not.

How to Measure Surface Resistivity

The SRM200 Surface Resistance Meter is an easy to use tester for measuring surface resistivity. This SRM200 uses parallel electrodes on the back of the meter to accurately measure RTT, RTG, or resistivity for periodic verification, factory audits or test lab evaluation of a product.

This meter is designed to be used in all facets of material production including engineering, maintenance, quality control, incoming inspection, manufacturing, research, or sales departments for the testing of anti-static mats, floor finishes, paints, wrist straps, smocks, footwear, bags and containers.

The SRM200 meets periodic test requirements per Compliance Verification ESD TR53 and conforms to ANSI/EOS/ESD (S4.1, S7.1, S12.1, S2.1).

October 19, 2011

Here at Transforming Technologies, we routinely receive phone calls and emails this time of year asking us how to prevent statics shocks around the home. While we love to help people when we can, the solutions and products we provide are geared more for manufacturing and the electronics fields. This is why I was very excited to read the popular blog Lifehacker explain common ways to eliminate static shocks in the home.

“One of the easiest ways to avoid static shock is to pay attention to what you’re wearing and what kind of fabrics make up the furniture in your house. For example, Electrostatics.net notes that rubber-soled shoes are great insulators, and will build up a lot of static in your body when combined with a wool or nylon carpet. Instead, try walking around in leather soled shoes, or cotton socks instead of wool socks. Leather soled shoes are also great for grocery shopping, since shopping carts can often cause lots of static electricity.

Similarly, wool sweaters are common offenders, especially in the dry winter (when you usually wear them). If you sit in a chair made out of the right fabric, you’ll build up quite a bit of static. Again, cotton is going to be much more friendly, so try wearing cotton clothes when you want to avoid nasty shocks. Certain furniture covers or antistatic sprays can help alleviate this problem, too.

You may have also noticed that often, when you get out of your car, you get a shock when you touch the door. You might have even heard that touching the door frame as you get out of the car can help, and that’s true. Make sure you start holding the metal frame before you get out of the car, and you keep touching it until you’re out of the seat completely. If you forget to do this, you can also touch the car door with your keys. Since the electricity will discharge through them, you won’t feel a shock”

Read the full article for more tips on avoiding static shocks in the dry air of the winter months.

October 5, 2011

Transforming Technologies is proud to announce the addition of the WBAS28 ESD Waste Basket to our line of Static Control Products.

Static Dissipative waste baskets keep highly charged waste receptacles away from sensitive electronic devices. Space efficient and economical, the WBAS28 fits under standard desk height. Rolled rims add strength, and are easy to clean. Ideal for cleanrooms, electronics manufacturing, inspection, quality control, and research laboratories. Made with a permanently dissipative, linear high density, black carbon loaded polypropylene.

Features:

For price and availability on the WBAS28 or for information on any products in Transforming Technologies full line of ESD products, please call 419-841-9552 or email eric@transforming-technologies.com.